Supporting copy for the Request Service

call out button.

Serving Nationwide

763-786-6940

Custom Thermoforming

Custom Thermoforming Services

At Alpha Plastics, we provide full plastic thermoforming, pressure forming and vacuum forming services. We have the expertise and experience needed to get your job done right. We have been providing quality services since 1976, and we have many satisfied customers.

Our range and expertise in thermoforming, pressure forming, and vacuum forming enable us to serve as both a Tier I and Tier II O.E.M. supplier, and we specialize in both short- and long-run production.

Our versatility in thermoforming includes pressure forming, drape forming, and free forming. We work with the benefits of each process to best produce the highest quality parts for our clients.

Contact us

today for more information about our custom thermoforming services and to request a quote.

Count on us for Accurate and Efficient Production

We work in a wide range of sizes, using plastic materials from .010" to .450" thick to produce parts as large as 5 feet x 8 feet, with a maximum draw or depth of 30", always using our expertise with draw ratios to select the proper base thickness and forming process. Materials that we work with include ABS, acrylics, and HMWPE with several others available.

With Lean Manufacturing standards in place, as well as a series of in-process and final inspections, you can be assured of accurate and efficient production at Alpha Plastics. Please see below for more information, or contact us today.

Thermoforming Specifications

General Capabilities:

Contract manufacturing, Tier I and Tier II O.E.M. suppliers

Length:

Max 5 ft. or 1524 mm

Width:

Max 8 ft. or 2438.4 mm

Draw:

Max 30 in or 762 mm

Thickness (Base Material)

Min:

.010 in or .254 mm

Max:

.450 in or 11.43 mm

Tolerance:

(+/-) ±.010 in

Material Suppliers:

Futurex, Kleerdex, Primex, Spartech

Materials:

ABS (Standard and Fire Retardant), acrylics, coextruded materials, polycarbonate, polyethylene, polystyrene, PVC

Molding Process:

Drape forming, free forming, pressure forming, vacuum forming

Equipment Capabilities:

Automated and manual

Production Volume:

Prototype, short-run, long-run, production capabilities

Quality Process Control:

In-process inspection, final inspections, first articles, production part approval process (PPAP)

Efficiency:

Lean manufacturing practices

Industry Focus:

Aerospace, agricultural, automotive, electronic, food, lawn and garden, lighting, marine, medical, motorcycle, packaging

(We can handle a large range of industries - if you don't see yours please inquire)

Intended Application:

ATV components, automotive interior components, reproduction parts, drip pans, electronic enclosures food equipment, P.O.P. displays, snowmobile components, vending machine components

Industry Standards:

ANSI - American National Standards Institute

ASTM - American Society for Testing and Materials

BAE Systems Standards

CE - The CE mark (officially CE marking) is a mandatory conformity

mark on many products placed on the single market in the European

Economic Area (EEA).

FAA - Federal Aviation Administration

FAR - Federal Aviation Regulations

FDA - Food And Drug Administration

ISO - International Organization for Standardization

Mil-Spec - Military Specifications

RoHS - Restriction Of Hazardous Substances (Compliant)

UL - Underwriters Laboratories

File Formats:

AutoCAD (DWG)

BMP - Bit Mapped Graphics

DXF - Drawing Interchange Format, or Drawing Exchange Format

GIF - Graphics Interchange Format

IGES - Initial Graphics Exchange Specification, ANSI file format.

Inventor (IDW, IPT)

JPG or JEPG - Joint Photographic Experts Group

PDF - Portable Document Format

Pro-E or Pro/Engineer (DRW, PRT, XPR)

SolidWorks (SLDPRT, SLDDRW, SLDDRT)

STEP - Standard for the Exchange of Product model data

TIFF - Tagged Image File Format

Request More Information

We specialize in thermoforming a diversified range of products for industrial and OEM accounts.

With the capability of handling parts with wall thickness of .030 to .400 and sizes up to 5' X 8' with a deep draw of 30", Alpha Plastics can deliver large or small parts for your customer needs.

763-786-6940

About Us

Alpha Plastics, a family owned and operated plastics fabrication company, has been supplying our customers with excellent quality, and rapid parts prototyping since 1976.

We specialize in difficult parts, and you can depend upon us for rapid prototyping that meets or exceeds your expectations. We're a member of SPE, Society of Plastic Engineers.

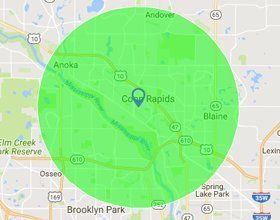

Find Us

Contact Us

Alpha Plastics Corp.

9315 Evergreen Blvd., NW

Coon Rapids, MN 55433

Phone: 763-786-6940

Fax: 763-786-4287

Privacy Policy

| Do Not Share My Information

| Conditions of Use

| Notice and Take Down Policy

| Website Accessibility Policy

© 2024

The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.